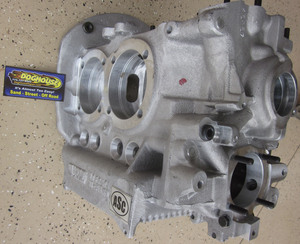

2387 short block - Phil's 'Penny Pincher' - sold

Part number:

phil's2387

Description:

It starts with an Autolinea pentroof super block with 7mm raised deck and 10mm case savers.

Already clearanced for my 86 stroke forged chromoly crank and 94 jugs, the set up prep work is (in no particular order):

1) set in the pinion gear with 3 shims

2) drill the main bearing saddle for Bugpack's racing main bearings

3) put in the steel backed single thrust cam bearings to hold my TCS20 Engle cam and Empi billet straight cut gears

4) mark the shaft for rod end clearancing if needed

5) clearance the bump on the bottom of the back of the block so my deep sump will fit w/o interference

6) massage the opening at the snout of the block to accept the slip in sand seal for the crank pulley

7) yank the fuel pump locate studs and install my turbo's oil return line adapter

8) install my FastFab oil block off plate on top of the block

9) drop in my 009 dist w/ compufire drop in module

10) modify the dist clamp to fit the bubble top case

11) smack the oil pump pickup tube assembly with a dead blow hammer to center the p/up tube

12) yank the oil pump studs out

13) yank the allen plugs and clean the block

14) dremel some rough burrs smooth inside the block

15) install the gears on the crank after cleaning the journals

16) loctite the journal plugs in the crank

17) prep the lifter bores for the Empi 30mm head drilled lobe lifters

18) prep the lifters & install, then check lobe to face clearance

19) tap and install the oil galley plug outside the oil pump in the block

20) engrave my DH in the block below the dist

21) yank the oil drain studs and replace with longer studs for the deep sump

22) weld the extended p/up tube to the stock one

23) get ready for the CB Perf H beam 5.5" rods and the CB Perf forged chromoly light flywheel

24) install the case savers (they're not installed anymore, they come loose for you to install)

25) clean and prep the stock oil drain plate and oil screen

26) pre-fit the head studs

27) pre-fit the CB Perf high perf oil pump and top drive gear

28) pre-fit the block halves together and torque mains for test spin of crank etc

29) put sealant on block halves, add main stud o-rings & cam plug - fasten block halves together & torque mains & surrounds

30) install deep sump, screen and drain plate

31) install oil pump & crank pulley

32) prep flywheel for install

33) set end play (took 4 shims) for .004 end play

34) torque Scat giant gland nut & washer on with a touch of red loctite to 290#s

Already clearanced for my 86 stroke forged chromoly crank and 94 jugs, the set up prep work is (in no particular order):

1) set in the pinion gear with 3 shims

2) drill the main bearing saddle for Bugpack's racing main bearings

3) put in the steel backed single thrust cam bearings to hold my TCS20 Engle cam and Empi billet straight cut gears

4) mark the shaft for rod end clearancing if needed

5) clearance the bump on the bottom of the back of the block so my deep sump will fit w/o interference

6) massage the opening at the snout of the block to accept the slip in sand seal for the crank pulley

7) yank the fuel pump locate studs and install my turbo's oil return line adapter

8) install my FastFab oil block off plate on top of the block

9) drop in my 009 dist w/ compufire drop in module

10) modify the dist clamp to fit the bubble top case

11) smack the oil pump pickup tube assembly with a dead blow hammer to center the p/up tube

12) yank the oil pump studs out

13) yank the allen plugs and clean the block

14) dremel some rough burrs smooth inside the block

15) install the gears on the crank after cleaning the journals

16) loctite the journal plugs in the crank

17) prep the lifter bores for the Empi 30mm head drilled lobe lifters

18) prep the lifters & install, then check lobe to face clearance

19) tap and install the oil galley plug outside the oil pump in the block

20) engrave my DH in the block below the dist

21) yank the oil drain studs and replace with longer studs for the deep sump

22) weld the extended p/up tube to the stock one

23) get ready for the CB Perf H beam 5.5" rods and the CB Perf forged chromoly light flywheel

24) install the case savers (they're not installed anymore, they come loose for you to install)

25) clean and prep the stock oil drain plate and oil screen

26) pre-fit the head studs

27) pre-fit the CB Perf high perf oil pump and top drive gear

28) pre-fit the block halves together and torque mains for test spin of crank etc

29) put sealant on block halves, add main stud o-rings & cam plug - fasten block halves together & torque mains & surrounds

30) install deep sump, screen and drain plate

31) install oil pump & crank pulley

32) prep flywheel for install

33) set end play (took 4 shims) for .004 end play

34) torque Scat giant gland nut & washer on with a touch of red loctite to 290#s

Availability:

Out of stock

We accept the following forms of payment: